TTD Insulated piercing connector (fire resistance)

Overview

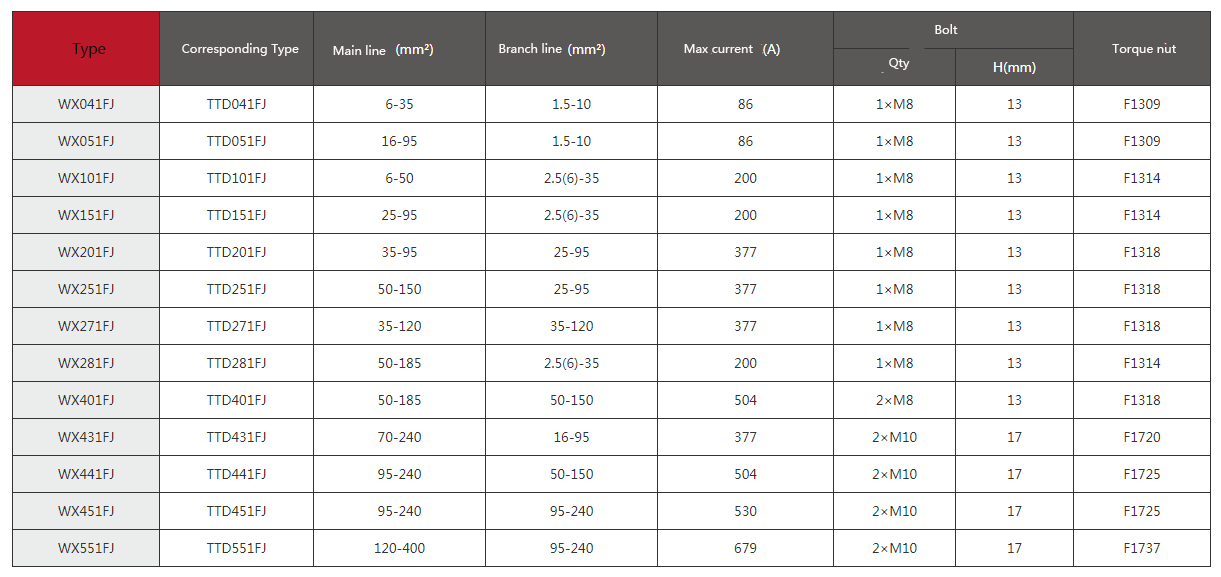

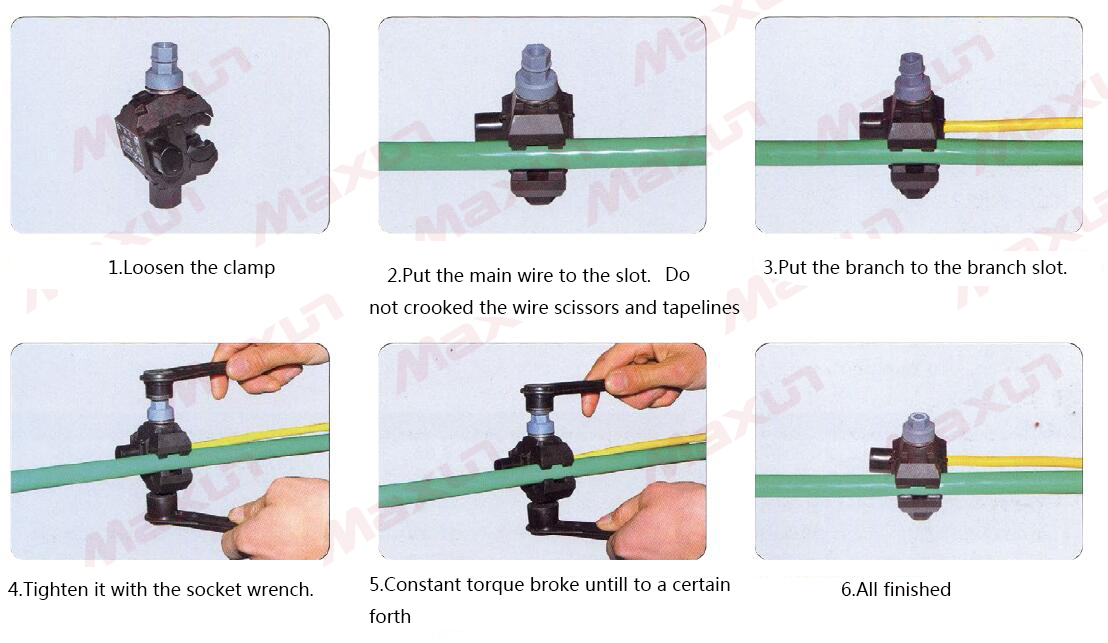

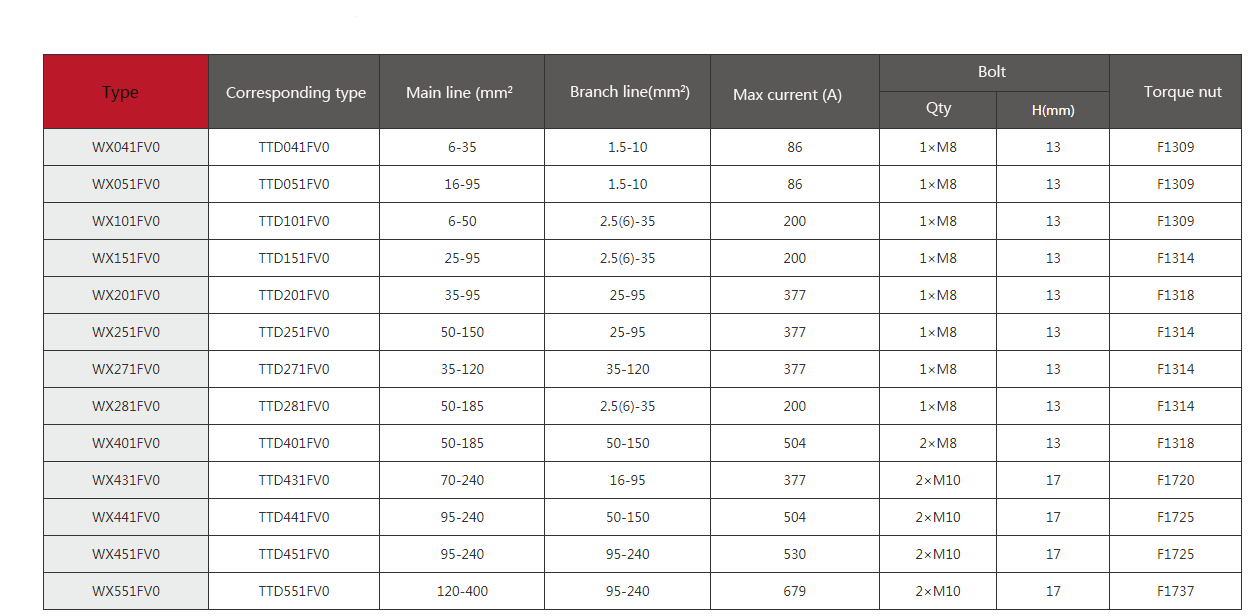

Aluminium alloy blades imbedded in moulded plastic and surrounded with a sealing compound insure electrical contact in LV overhead distribution networks. A single torque control nut draws the two parts of the connector together and shears off when the teeth have pierced the insulation and made contact with the conductor strands.

Material

Body: Thermoplastic polyamide 66 with fiberglass

Connecting bridge: Copper tinned , Brass tinned, Al

Sealing parts: Flexible PVC

End cap: Flexible PVC

Grease: Silica gel

Bolt: Hot dip glavanized steel, 8.8 grade

Washer, Nut: Hot dip glavanized steel

Fuse nut: Zinc alloy

High Standard Insulated Piercing Connector Of Flame Resisitance

TTD insulating piercing Connector wtih best price is suitable for majority types of LV ABC conductors as well as connections to service and lighting cable cores.When tightening the bolts, the teeth of the contact plates penetrate the insulation and establish a perfect contact. The bolts are tightened until the heads shear off. Tightening torque guaranteed (fuse nut). Stripping of insulation is avoided.

Service condition: 400/600V, 50/60Hz, -10°C to 55°C

Ease of installation has been combined with excellent mechanical, electrical and environmental characteristics to provide a connector capable of terminating Aluminium or Copper stranded conductors.